In the lyophilisation process, some experts may miss to review and choose a better type of freeze drying tray, which can have a significant influence on lyophilisation process efficiency. In consideration of selecting the appropriate tray, there are key concerns to be considered, such as material compatibility, operation efficiency, including cleaning and maintenance, sterilization requirement, contamination risks, heat transfer efficiency, temperature uniformity, and, of course, cost and reliability.

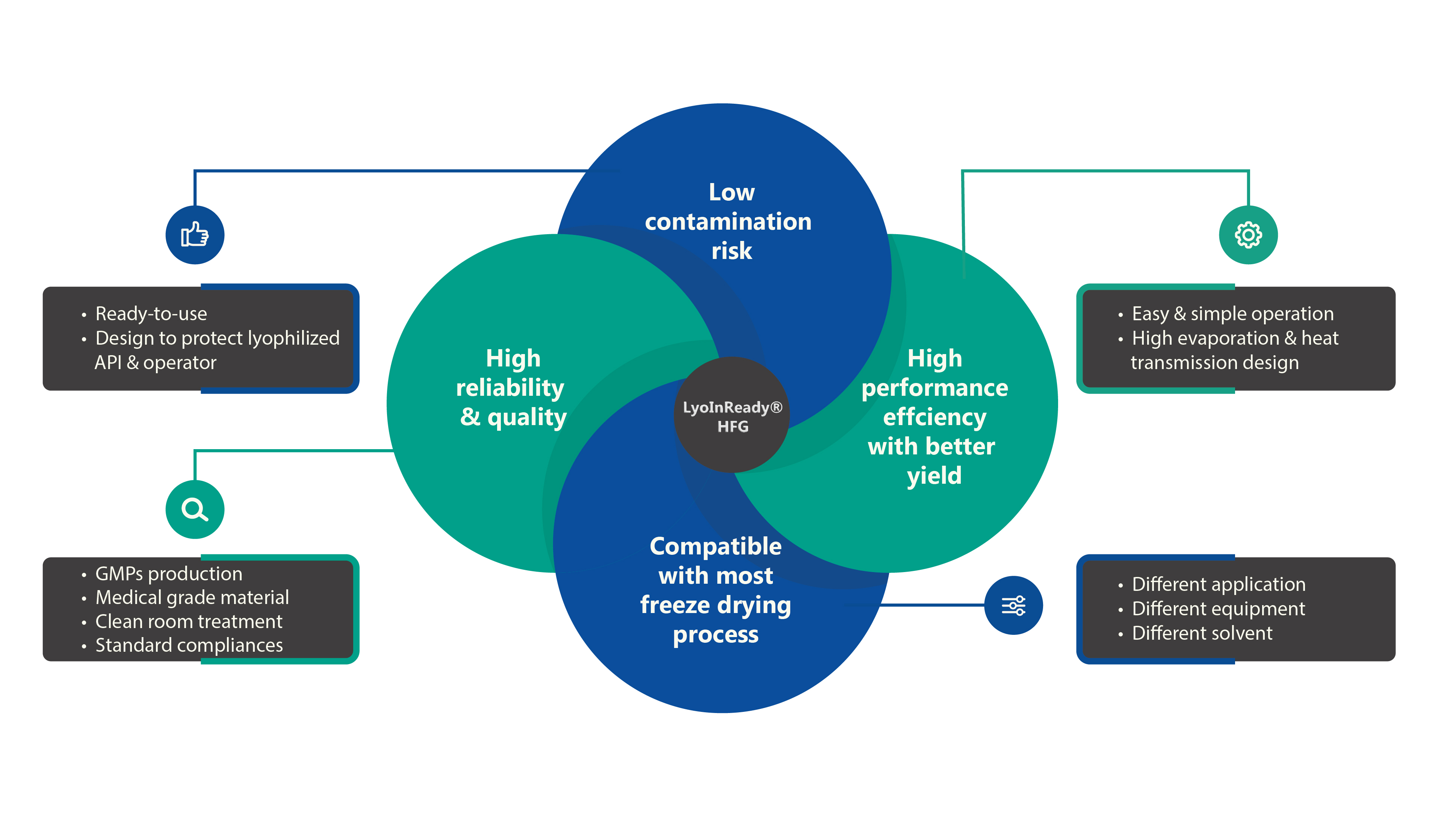

LyoInReady® High efficiency Freeze-drying Guard tray is a ready-to-use freeze-drying tray with a unique design to make lyophilization processes easier, and more efficient with better yield. It can reduce significantly operation time and complications as well as contamination risk while optimizing process efficiency. It is for the direct replacement of either any traditional open stainless-steel trays or any other disposable trays without high performance efficiency. LyoInReady® HFG tray is an ideal bulk freeze-drying container because:

Production Description

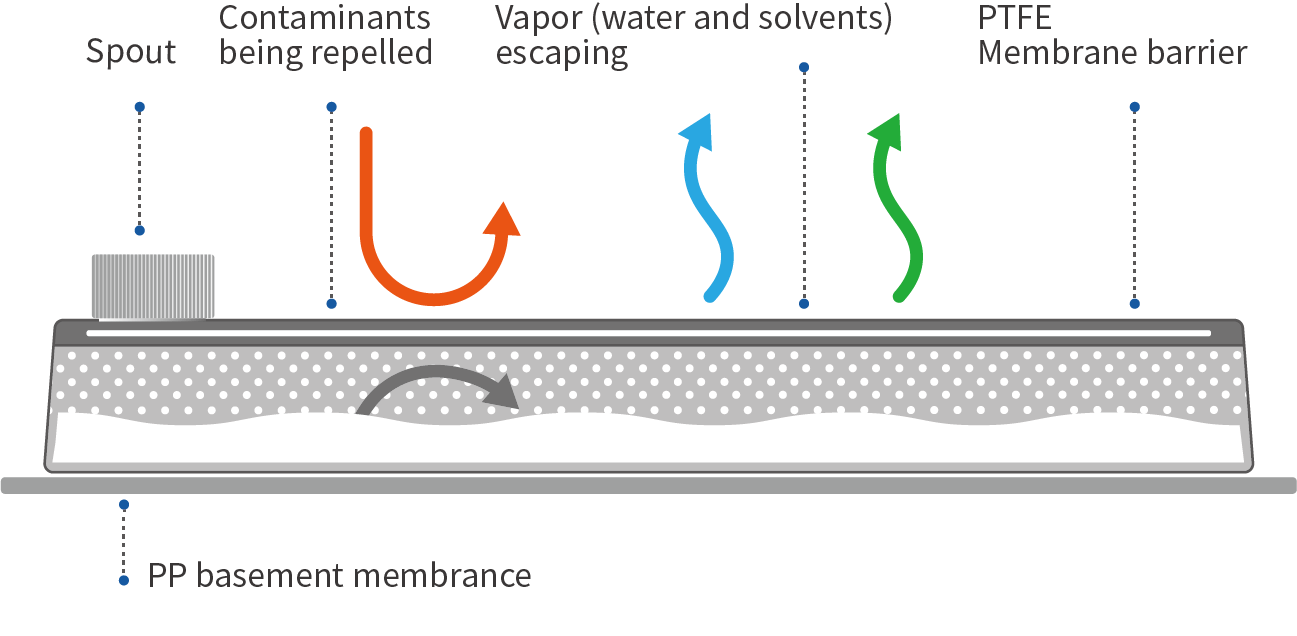

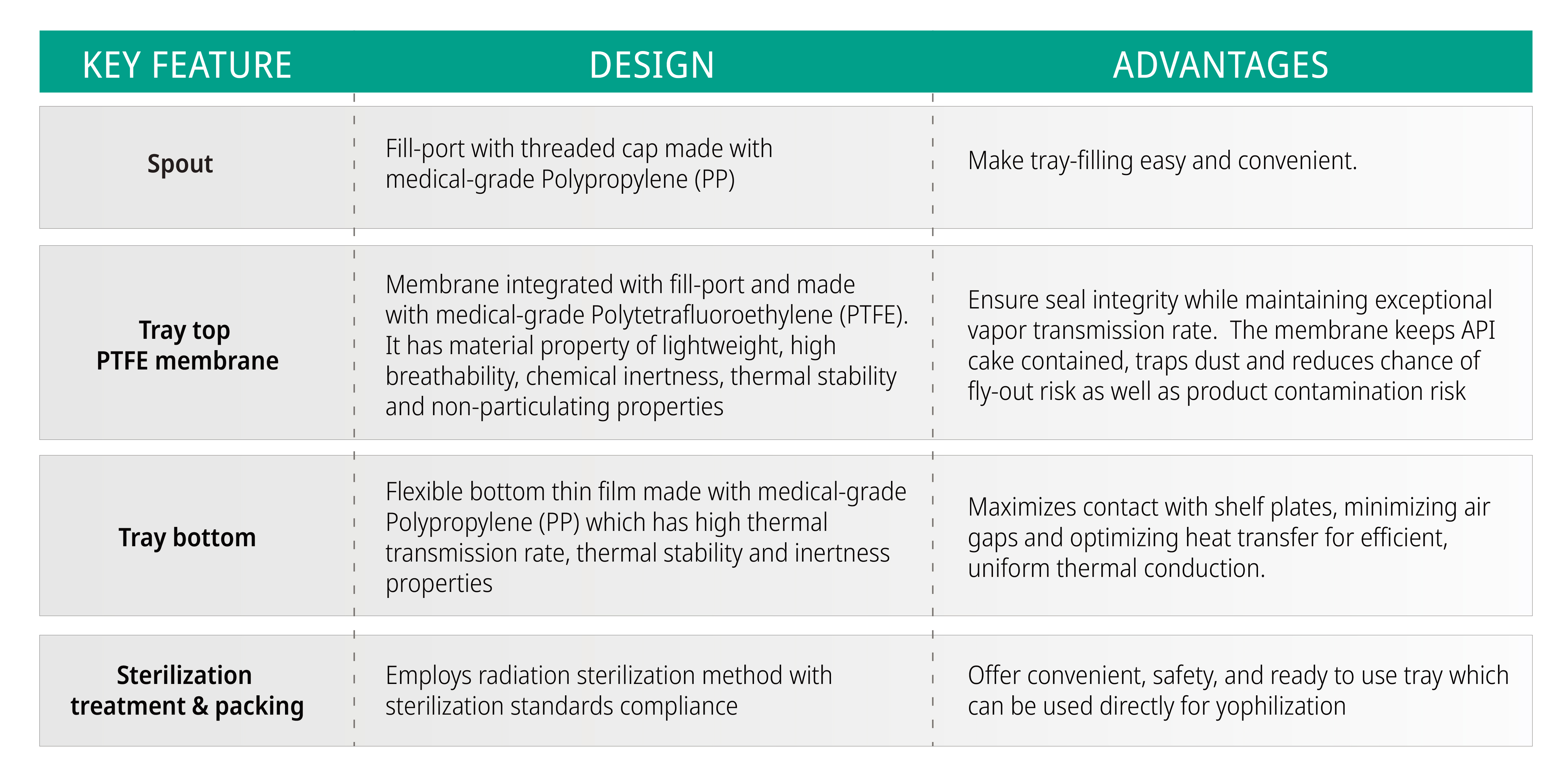

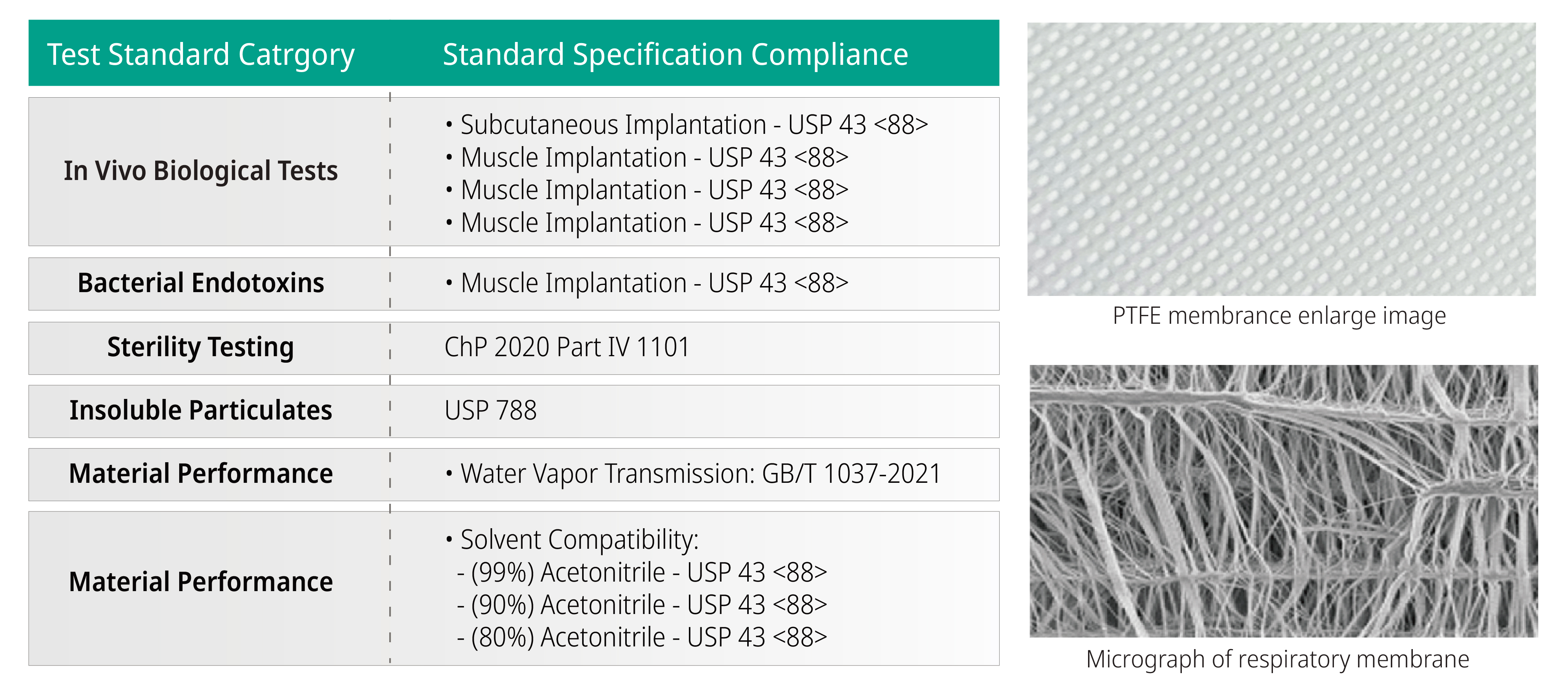

LyoInReady® High Efficiency Freeze-Drying Guard tray is ready to use, a disposable, fully enclosed container that uses PTFE membrane technology to contain and protect lyophilized active pharmaceutical ingredient (API) during the entire freeze-drying process. It is compatible with most of the freeze-drying processes and equipment and significantly reducing cleaning time and verification costs. The tray's bottom features a flexible PP bottom film that maintains close contact with the shelf, ensuring efficient and uniform heat transfer. Utilizing PTFE membrane technology, the breathable membrane combines excellent high vapor transmission rates with effective prevention of product splashing or overflow, eliminating cross-contamination risks while enhancing product recovery rates.

Product Key Features and Advantages

LyoInReady® High Efficiency Freeze-Drying Guard tray has a unique design engineered to support high heat transmission efficiency and maintain temperature uniformity while providing excellent barrier protection and reducing fly out of lyophilized liquid API. With the key features designed, LyoInReady® HFG tray has a superior combination of performance advantages in efficiency and reliability.

Applications

LyoInReady® High Efficiency Freeze-Drying Guard tray is designed to eliminate a lot of cleaning operations and reduce the chances of lyophilized API fly-out risk and contamination risk. And does enables greater safety in lyophilization process and improves process efficiency. Basically, the tray is suitable for different kinds of batch freeze-drying and freeze-drying process development, but especially worthy for clinical staging and large-scale production of biological agents such as peptides, oligonucleotides, proteins, drug intermediates, polysaccharides, strains, and other active pharmaceutical ingredients and HPAPI. Also, it supports formulations for nanoparticles lyophilisation and free-drying of bacteria because of its unique features.

Quality & Reliability

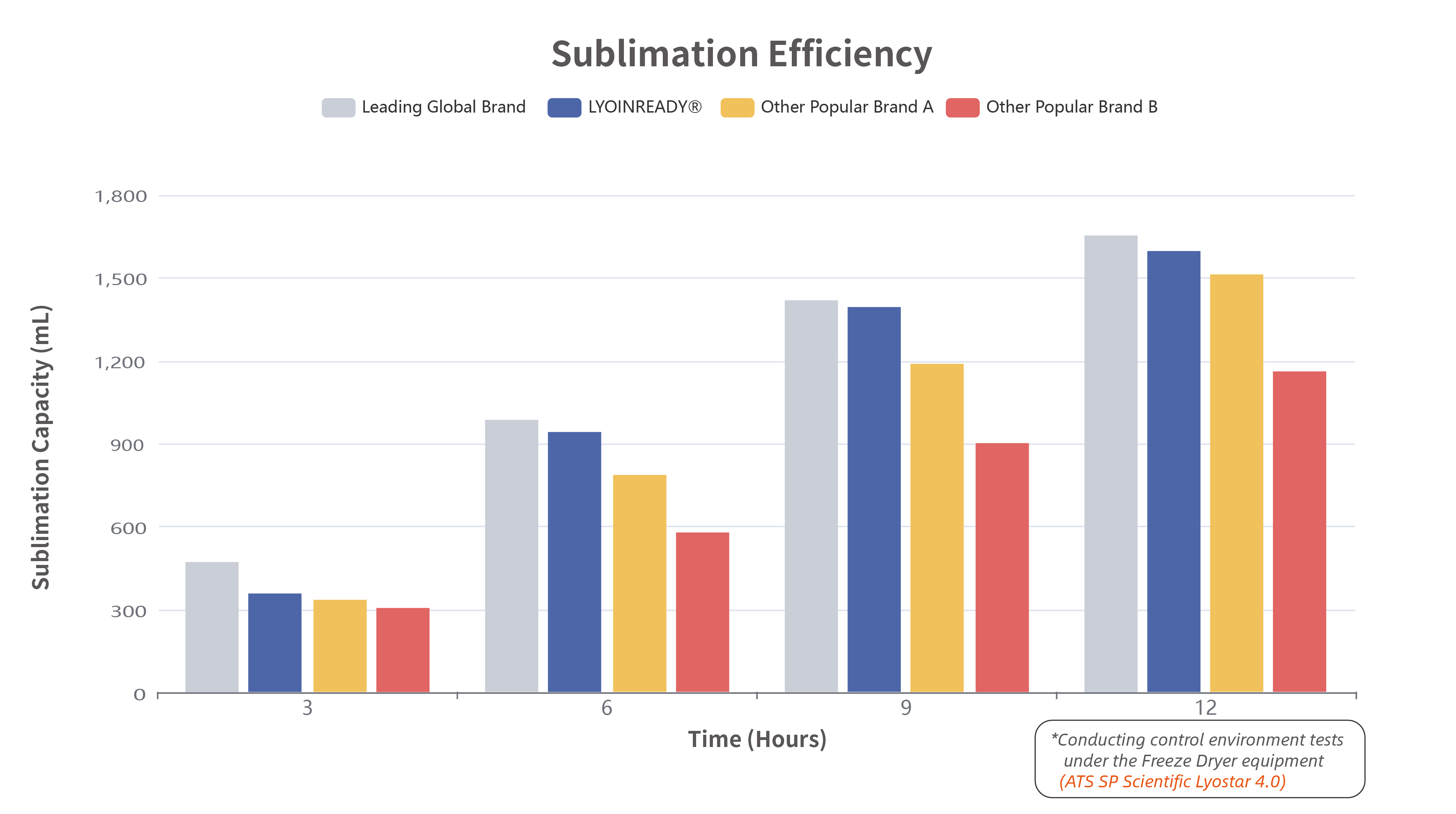

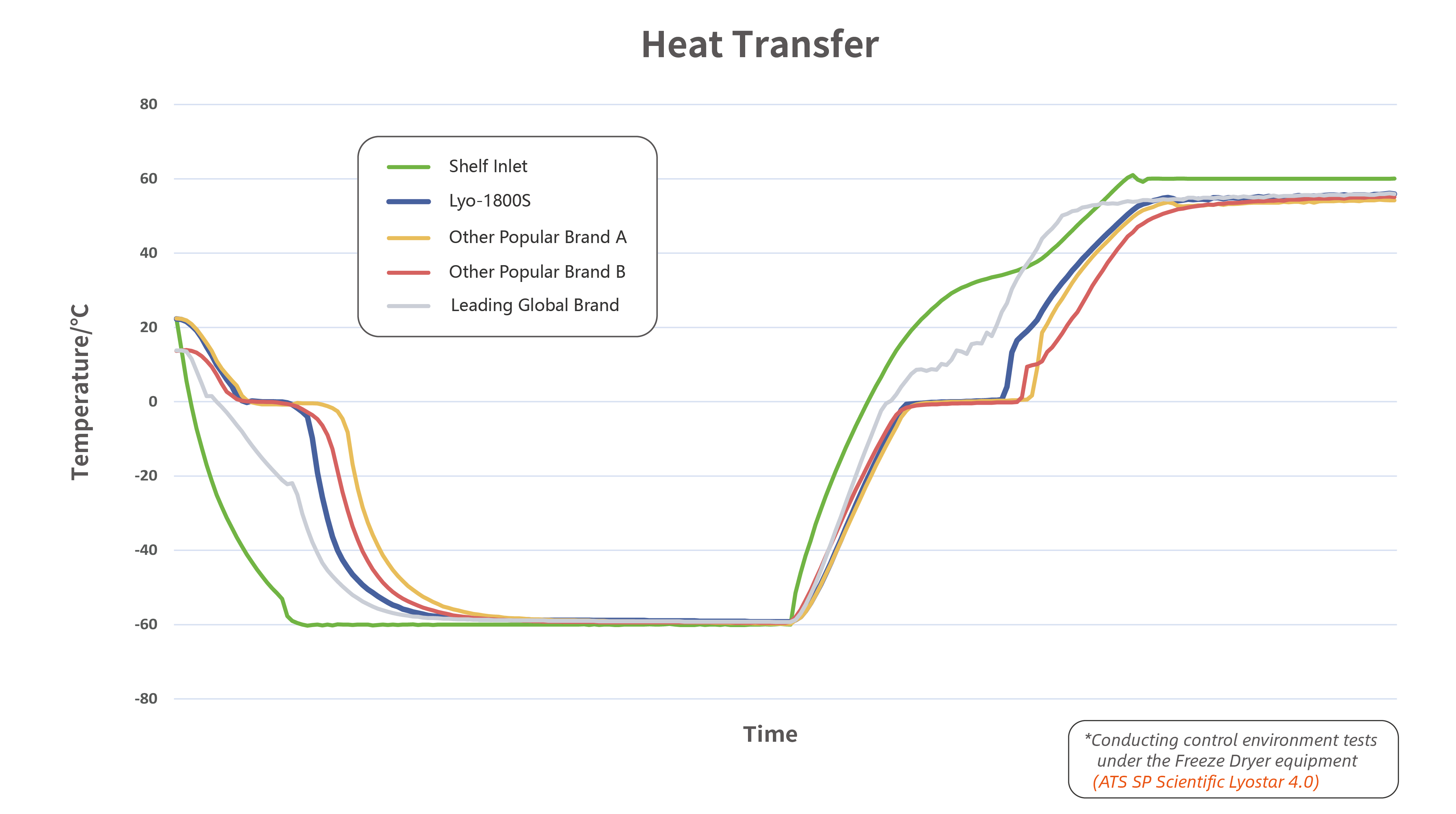

LyoInReady® High Efficiency Freeze-Drying Guard tray is leading in performance efficiency in the freeze-drying tray market. LyoInReady® HFG tray shows compelling performance quality in the lyophilisation efficiency test as below:

LyoInReady® HFG tray quality is assured as it is produced under relevant Good Manufacturing Practices (GMPs), and core materials are medical grade. Also, product packaging, sterilization, and final inspection are conducted in a clean room environment. Moreover, product reliability is guaranteed with standard compliance as below:

If you have any enquirues,please contact: [email protected]

Leave a Comment